Your Vision, Machined to Perfection

Tight tolerances. Complex parts. U.S.-made precision with speed, consistency, and full engineering support.

Where Precision Meets Possibility

Engineered for Demanding Tolerances. Built for What’s Next.

From micro-diameter components to full assemblies, BoldX delivers precision machining solutions trusted by aerospace, medical, industrial, and emerging tech leaders. With over five decades of experience and a continually upgraded fleet of cutting-edge equipment, we turn complex specifications into consistent, production-ready parts—down to tolerances as tight as 2 microns.

Our advanced Swiss turning, multi-spindle, EDM, grinding, and 5-axis milling capabilities allow us to reduce scrap rates, minimize secondary operations, and accelerate lead times without compromising quality. Whether you’re scaling high-volume runs or solving for intricate geometries, BoldX provides the speed, accuracy, and flexibility to get it done right.

Precision at Every Stage. Flexibility in Every Build.

From ultra-small diameters to complex assemblies, BoldX offers a full range of precision manufacturing capabilities designed to meet the most demanding specs. Whether you're scaling production or solving a one-of-a-kind challenge, our team, technology, and processes are built to deliver—with consistency, speed, and care.

- Precision machining diameters from .004" (0.102 mm) to 10" (76.2 mm)

- Lengths up to 24" (609.6 mm)

- Tolerances down to 2 microns (.00008")

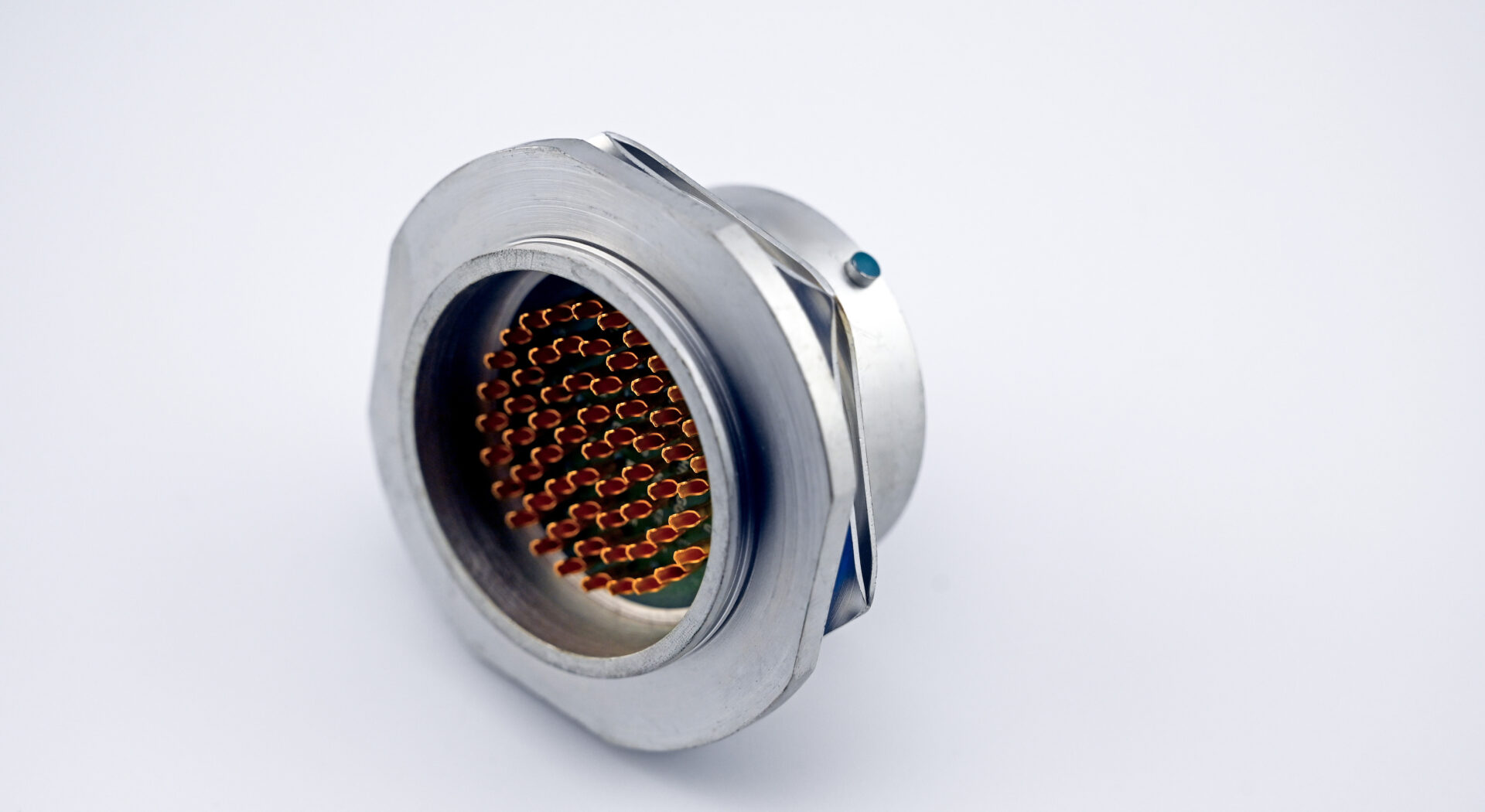

- Small parts assembly and sub-assembly

- Glass-to-metal sealing for connectors, headers, and pass-throughs

- Materials: Steel, stainless, aluminum, copper alloys, aircraft-grade and precious metals

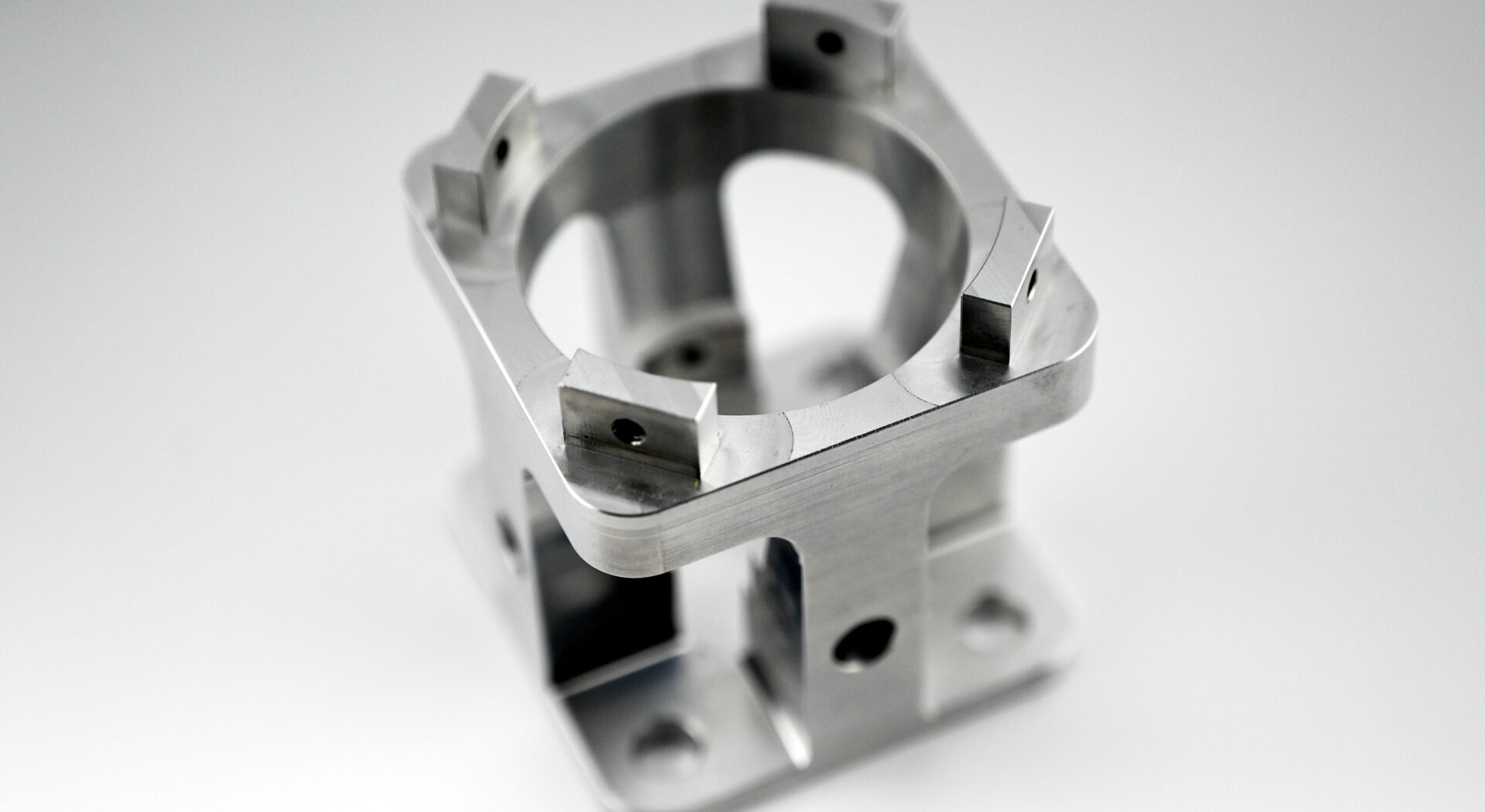

- Shapes: Rounds, hexes, squares, and custom geometries

- Engineering support for design and manufacturability

- Complete secondary operations, including I.D., O.D., and centerless grinding

- Plating, heat treat, deburring, and more

- Flexible and cellular manufacturing systems

Core Capabilities:

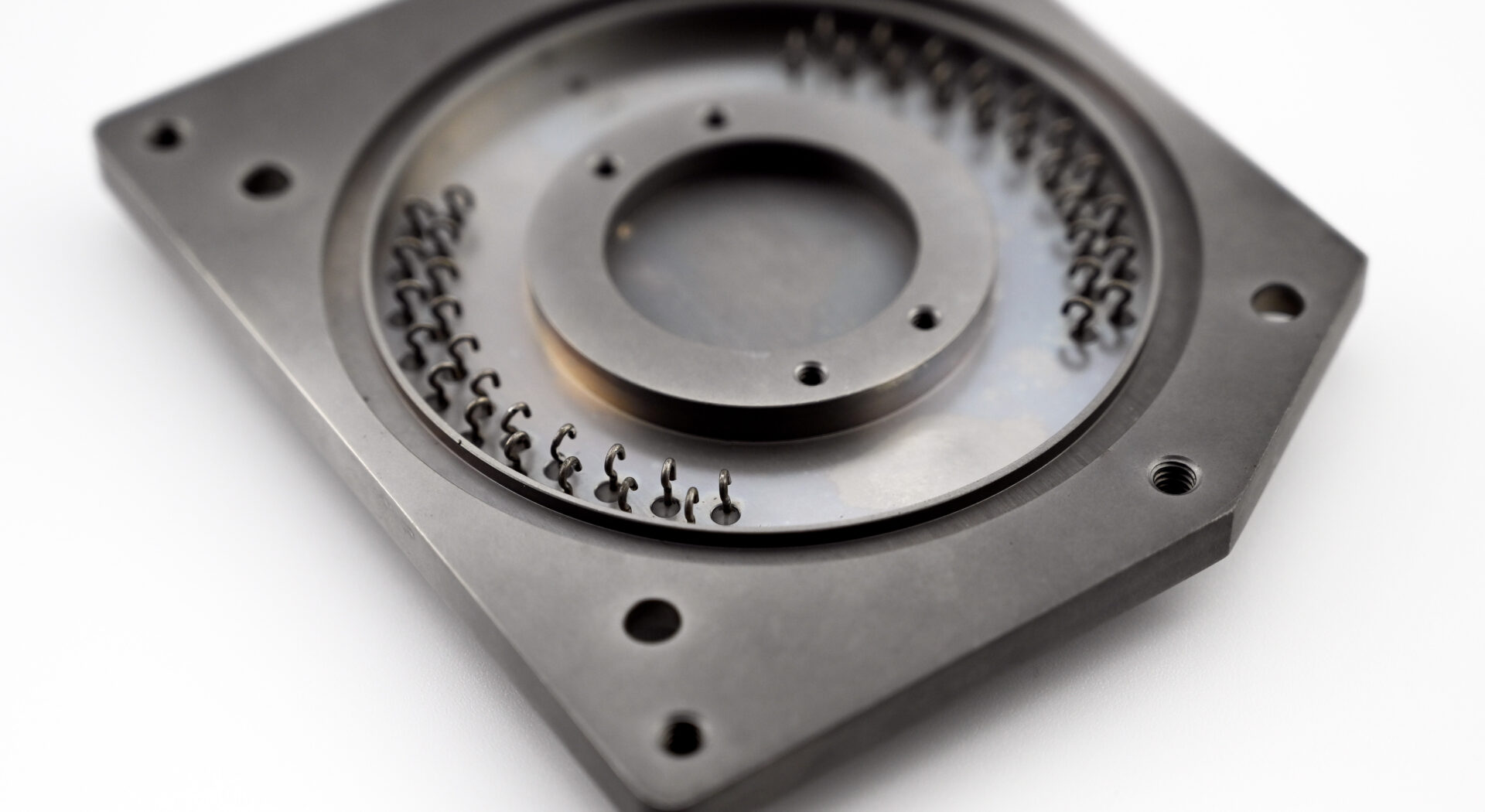

Complex Geometries. Simplified Execution.

At BoldX, multi-axis machining is more than a capability—it’s a competitive advantage. Our advanced 4- and 5-axis CNC systems allow us to machine intricate parts in fewer setups, with higher accuracy, tighter tolerances, and shorter lead times.

Ideal for aerospace, medical, and other spec-critical applications, our multi-axis capabilities support everything from precision contours to angled features and undercuts that traditional machining can’t reach. The result? Greater consistency, reduced cost, and faster production cycles—even for your most complex parts.

Tolerances & Dimensional Capabilities

Built to Spec. Held to Microns.

BoldX specializes in manufacturing components that demand extreme dimensional precision. With capabilities refined over decades and advanced equipment to match, we routinely hold tolerances down to 2 microns (0.00008") across a wide range of geometries and materials.

- Diameters: from .004" (0.102 mm) to 3" (76.2 mm)

- Lengths: up to 24" (609.6 mm)

- Tolerances: down to 2 microns, depending on material and part complexity

Whether you're producing miniature components or precision-matched assemblies, our team works closely with yours to ensure every part meets exact specs—no overages, no surprises.

At BoldX, tight tolerances aren’t a challenge—they’re standard.

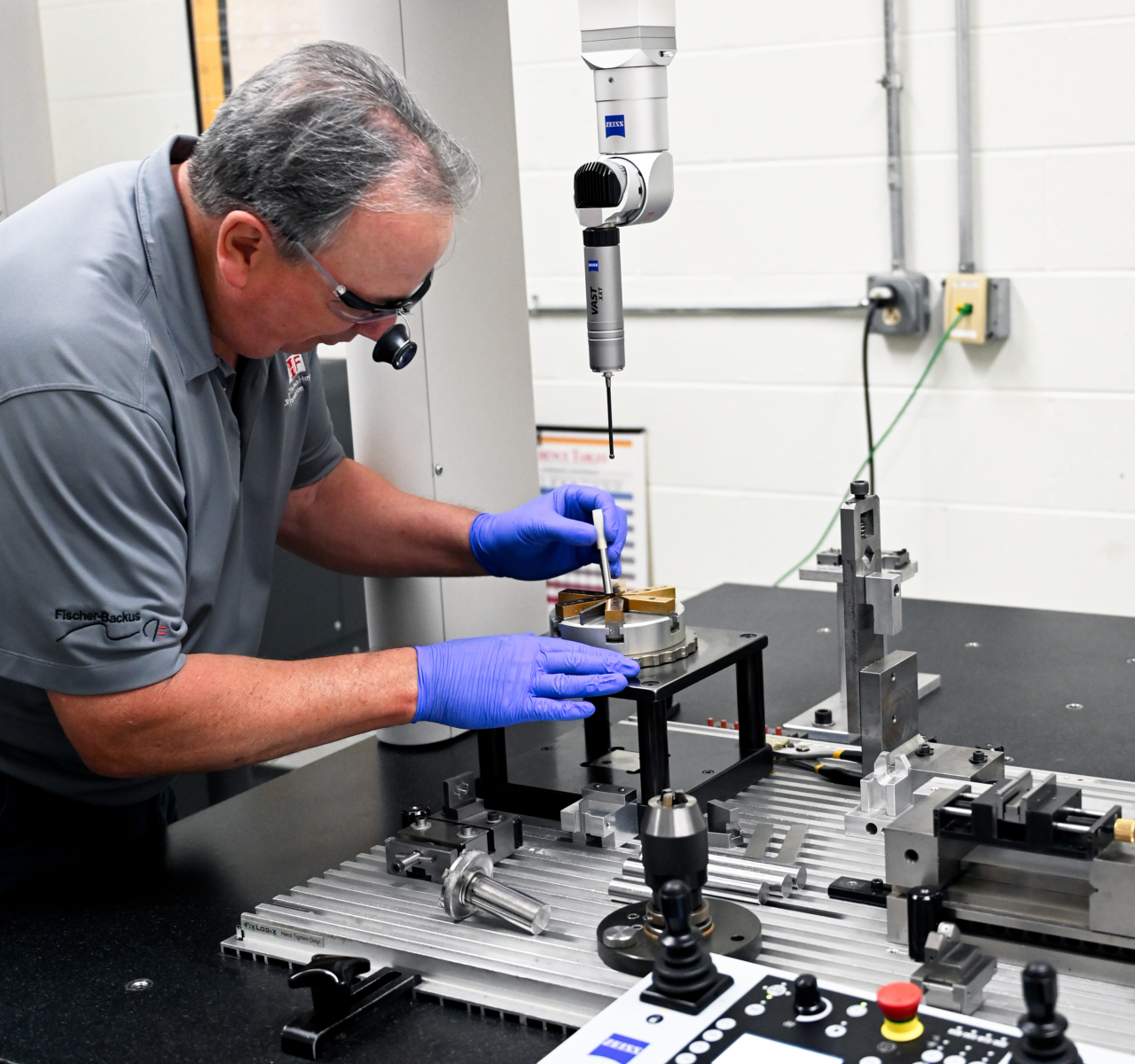

Inspection & Quality Assurance

Every Detail Checked. Every Part Trusted. At BoldX, quality isn’t just a checkpoint—it’s a commitment built into every stage of production. Our inspection process is designed to meet the highest industry standards, ensuring each part performs exactly as intended, no matter how complex or mission-critical.

We combine advanced metrology tools with hands-on expertise to deliver uncompromising accuracy:

- Hand-Inspected Quality: Every part undergoes manual inspection for fit, finish, and spec compliance by trained technicians—because nothing replaces the human eye for detail.

- Cleanroom Inspection & Assembly: For medical, aerospace, and other high-purity applications, we offer cleanroom environments to ensure parts meet strict contamination control standards.

- Micron-Level Tolerance Verification: Our team uses precision measurement systems to validate critical dimensions, surface finishes, and tight tolerances—down to the micron.

From prototype to production, BoldX delivers audit-ready documentation, full traceability, and peace of mind. When your product can’t fail, our inspection process won’t miss.